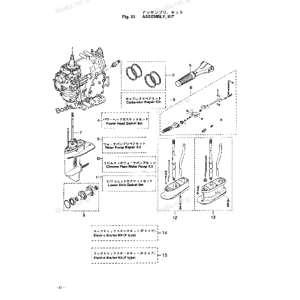

346-87122-0 CARBURETOR REPAIR KIT Nissan

NS25C3, NS30A4

CARBURETOR

Price: query

Rating:

You can buy parts:

As an associate, we earn commssions on qualifying purchases through the links below

Car Carburetor Repair Kit, for MERC&ruiser, for 30HP 25HP 346871220M 346871220 853780A1 346-87122-0

Easy to use, light weight and easy to carry. || Made of high-quality ABS plastic material, it has high hardness, good strength and long service life. || The engine gasket set has high precision and sensitivity to improve vehicle safety. || Since this product is manufactured in accordance with OE requirements, it is very suitable for replacing damaged parts. || Please verify the model and size before ordering to ensure that this is the correct part. Thank you for your understanding and support.

Easy to use, light weight and easy to carry. || Made of high-quality ABS plastic material, it has high hardness, good strength and long service life. || The engine gasket set has high precision and sensitivity to improve vehicle safety. || Since this product is manufactured in accordance with OE requirements, it is very suitable for replacing damaged parts. || Please verify the model and size before ordering to ensure that this is the correct part. Thank you for your understanding and support.

Outboard Carburetor Repair Kit Compatible With 30 25 NS30A3 NS30A4 NS25C2 NS25C3 346871220M 346871220 346-87122-0 853780A1

YFLRHENJ Compatible: Fits models NS30A3, NS30A4, NS25C2, NS25C3 Compatible With integration. || : Designed Compatible With longevity, ensuring your outboard runs efficiently. || Comprehensive: Includes all essential components Compatible With complete carburetor repair. || Versatile: Suitable Compatible With various outboard models Compatible With broad application. || User-friendly: Easy installation process Compatible With quick and hassle-free repairs. || Cost-effective: A practical solution to restore your carburetor without excessive costs. || Reliable: Designed to enhance performance and fuel efficiency in your outboard engine.

YFLRHENJ Compatible: Fits models NS30A3, NS30A4, NS25C2, NS25C3 Compatible With integration. || : Designed Compatible With longevity, ensuring your outboard runs efficiently. || Comprehensive: Includes all essential components Compatible With complete carburetor repair. || Versatile: Suitable Compatible With various outboard models Compatible With broad application. || User-friendly: Easy installation process Compatible With quick and hassle-free repairs. || Cost-effective: A practical solution to restore your carburetor without excessive costs. || Reliable: Designed to enhance performance and fuel efficiency in your outboard engine.

ZFQMGDD Carburetor Repair Kit for Tohatsu 25HP M30A4 30HP M25C M30A3 M25C2 M25C3 346-87122-0 346871220 346871220M 853780A1 Motorcycle Accessories

ZFQMGDD Fine workmanship || 100% brand new and high quality. || Made of high quality material, durable and practical to use. || Delicate and exquisite, highly match the equipment. || Solid and durable, long service life. || Easy to install and reliable to use.

ZFQMGDD Fine workmanship || 100% brand new and high quality. || Made of high quality material, durable and practical to use. || Delicate and exquisite, highly match the equipment. || Solid and durable, long service life. || Easy to install and reliable to use.

Nissan entire parts catalog list:

Information:

Drain the Cooling System

Stop the engine and allow the engine to cool. Ensure that the engine will not start when the cooling system is drained.

Illustration 1 g00781022

Loosen the cooling system filler cap slowly in order to relieve any pressure. Remove the cooling system filler cap.

Illustration 2 g00719046

Drain plugs on the oil cooler, water pumps, and elbows

Open the cooling system drain valve. Remove the drain plugs.

Dispose of used engine coolant properly or recycle. Various methods have been proposed to reclaim used coolant for reuse in engine cooling systems. The full distillation procedure is the only method acceptable by Caterpillar to reclaim the used coolant.

For information regarding the disposal and the recycling of used coolant, consult your Caterpillar dealer or consult Caterpillar Dealer Service Tools:Outside Illinois 1-800-542-TOOL

Inside Illinois 1-800-541-TOOL

Canada 1-800-523-TOOL

Clean the Cooling System

After the cooling system has been drained, flush the cooling system with clean water in order to remove any debris.

Close the cooling system drain valve. Clean the drain plugs and install the plugs.

Use of commercially available cooling system cleaners may cause damage to cooling system components. Use only cooling system cleaners that are approved for Caterpillar engines.

Fill the cooling system no faster than 19 L (5 US gal) per minute to avoid air locks.

Fill the cooling system with a mixture of clean water and Caterpillar Fast Acting Cooling System Cleaner. Add 0.5 L (1 pint) of cleaner per 15 L (4 US gal) of the cooling system capacity. Install the cooling system filler cap.

Start the engine. Operate the engine for a minimum of 30 minutes with a coolant temperature of at least 82 °C (180 °F).

Stop the engine and allow the engine to cool. Loosen the cooling system filler cap slowly in order to relieve any pressure. Remove the cooling system filler cap. Open the cooling system drain valve. Remove the drain plugs.

Improper or incomplete rinsing of the cooling system can result in damage to copper and other metal components.To avoid damage to the cooling system, make sure to completely flush the cooling system with clear water. Continue to flush the system until all signs of the cleaning agent are gone.

Allow the water to drain. Flush the cooling system with clean water until the water that drains is clean. Close the cooling system drain valve. Clean the drain plugs and install the plugs. Cleaning a Cooling System that has Heavy Deposits or Plugging

Note: For the following procedure to be effective, there must be an active flow through the cooling system components.

After the cooling system has been drained, flush the cooling system with clean water in order to remove any debris.

Close the cooling system drain valve. Clean the drain plugs and install the plugs.

Use of commercially available cooling system cleaners may cause damage to cooling system components. Use only cooling system cleaners that are approved for Caterpillar engines.

Fill the cooling system no faster than 19 L (5 US gal) per minute to avoid air locks.

Fill the cooling system with a mixture of clean water and Caterpillar Fast Acting Cooling System Cleaner. Add 0.5 L (1 pint) of cleaner per 3.8 to 7.6 L (1 to 2 US gal) of the cooling system capacity. Install the cooling system filler cap.

Start the engine. Operate the engine for a minimum of 90 minutes with a coolant temperature of at least 82 °C (180 °F).

Stop the engine and allow the engine to cool. Loosen the cooling system filler cap slowly in order to relieve any pressure. Remove the cooling system filler cap. Open the cooling system drain valve. Remove the drain plugs. Allow the water to drain.

Improper or incomplete rinsing of the cooling system can result in damage to copper and other metal components.To avoid damage to the cooling system, make sure to completely flush the cooling system with clear water. Continue to flush the system until all signs of the cleaning agent are gone.

Flush the cooling system with clean water until the water that drains is clean. Close the cooling system drain valve. Clean the drain plugs and install the plugs. Fill the Cooling System

Fill the cooling system no faster than 19 L (5 US gal) per minute to avoid air locks.

Note: For information about the proper coolant to use, see this Operation and Maintenance Manual, "Refill Capacities and Recommendations" (Maintenance Section). For the capacity of the cooling system, see this Operation and Maintenance Manual, "Refill Capacities and Recommendations" (Maintenance Section).

Fill the cooling system with coolant/antifreeze. Do not install the cooling system filler cap.

Start the engine. Operate the engine in order to purge the air from the cavities of the engine block. Allow the coolant to warm and allow the coolant level to stabilize. Stop the engine.

Check the coolant level. Maintain the coolant to the prop

Stop the engine and allow the engine to cool. Ensure that the engine will not start when the cooling system is drained.

Illustration 1 g00781022

Loosen the cooling system filler cap slowly in order to relieve any pressure. Remove the cooling system filler cap.

Illustration 2 g00719046

Drain plugs on the oil cooler, water pumps, and elbows

Open the cooling system drain valve. Remove the drain plugs.

Dispose of used engine coolant properly or recycle. Various methods have been proposed to reclaim used coolant for reuse in engine cooling systems. The full distillation procedure is the only method acceptable by Caterpillar to reclaim the used coolant.

For information regarding the disposal and the recycling of used coolant, consult your Caterpillar dealer or consult Caterpillar Dealer Service Tools:Outside Illinois 1-800-542-TOOL

Inside Illinois 1-800-541-TOOL

Canada 1-800-523-TOOL

Clean the Cooling System

After the cooling system has been drained, flush the cooling system with clean water in order to remove any debris.

Close the cooling system drain valve. Clean the drain plugs and install the plugs.

Use of commercially available cooling system cleaners may cause damage to cooling system components. Use only cooling system cleaners that are approved for Caterpillar engines.

Fill the cooling system no faster than 19 L (5 US gal) per minute to avoid air locks.

Fill the cooling system with a mixture of clean water and Caterpillar Fast Acting Cooling System Cleaner. Add 0.5 L (1 pint) of cleaner per 15 L (4 US gal) of the cooling system capacity. Install the cooling system filler cap.

Start the engine. Operate the engine for a minimum of 30 minutes with a coolant temperature of at least 82 °C (180 °F).

Stop the engine and allow the engine to cool. Loosen the cooling system filler cap slowly in order to relieve any pressure. Remove the cooling system filler cap. Open the cooling system drain valve. Remove the drain plugs.

Improper or incomplete rinsing of the cooling system can result in damage to copper and other metal components.To avoid damage to the cooling system, make sure to completely flush the cooling system with clear water. Continue to flush the system until all signs of the cleaning agent are gone.

Allow the water to drain. Flush the cooling system with clean water until the water that drains is clean. Close the cooling system drain valve. Clean the drain plugs and install the plugs. Cleaning a Cooling System that has Heavy Deposits or Plugging

Note: For the following procedure to be effective, there must be an active flow through the cooling system components.

After the cooling system has been drained, flush the cooling system with clean water in order to remove any debris.

Close the cooling system drain valve. Clean the drain plugs and install the plugs.

Use of commercially available cooling system cleaners may cause damage to cooling system components. Use only cooling system cleaners that are approved for Caterpillar engines.

Fill the cooling system no faster than 19 L (5 US gal) per minute to avoid air locks.

Fill the cooling system with a mixture of clean water and Caterpillar Fast Acting Cooling System Cleaner. Add 0.5 L (1 pint) of cleaner per 3.8 to 7.6 L (1 to 2 US gal) of the cooling system capacity. Install the cooling system filler cap.

Start the engine. Operate the engine for a minimum of 90 minutes with a coolant temperature of at least 82 °C (180 °F).

Stop the engine and allow the engine to cool. Loosen the cooling system filler cap slowly in order to relieve any pressure. Remove the cooling system filler cap. Open the cooling system drain valve. Remove the drain plugs. Allow the water to drain.

Improper or incomplete rinsing of the cooling system can result in damage to copper and other metal components.To avoid damage to the cooling system, make sure to completely flush the cooling system with clear water. Continue to flush the system until all signs of the cleaning agent are gone.

Flush the cooling system with clean water until the water that drains is clean. Close the cooling system drain valve. Clean the drain plugs and install the plugs. Fill the Cooling System

Fill the cooling system no faster than 19 L (5 US gal) per minute to avoid air locks.

Note: For information about the proper coolant to use, see this Operation and Maintenance Manual, "Refill Capacities and Recommendations" (Maintenance Section). For the capacity of the cooling system, see this Operation and Maintenance Manual, "Refill Capacities and Recommendations" (Maintenance Section).

Fill the cooling system with coolant/antifreeze. Do not install the cooling system filler cap.

Start the engine. Operate the engine in order to purge the air from the cavities of the engine block. Allow the coolant to warm and allow the coolant level to stabilize. Stop the engine.

Check the coolant level. Maintain the coolant to the prop

Parts carburetor Nissan:

3P0-03200-0