346-76010-0 STARTER MOTOR Nissan

NS25C3, NS30A4, NS40C

STARTER

Price: query

Rating:

You can buy parts:

As an associate, we earn commssions on qualifying purchases through the links below

Marine Outboard Starter Motor Compatible With NS25 NS30 M25 M30 2-Stroke Models 346-76010-0A0 346-76010-0 346-76010-0M

HryJRAW Durability: Designed to withstand harsh marine conditions Compatible with performance. || Compatibility: Engineered Compatible with a fit with and marine outboard engines. || Efficiency: Optimizes engine start- to ensure smooth on the water every time. || Reliability: Dependable design ensures consistent starting power when you need it most. || Installation: User-friendly design allows Compatible with easy installation with minimal tools required

HryJRAW Durability: Designed to withstand harsh marine conditions Compatible with performance. || Compatibility: Engineered Compatible with a fit with and marine outboard engines. || Efficiency: Optimizes engine start- to ensure smooth on the water every time. || Reliability: Dependable design ensures consistent starting power when you need it most. || Installation: User-friendly design allows Compatible with easy installation with minimal tools required

346-76010 Starter Motor 9 Tooth Compatible With Tohatsu Outboard M25C M30C M40C 346-76010-0

DUANLOUS Strong power: Starter Motor can provide powerful torque, making the engine easy to start. Even in cold weather, it can quickly respond and start the engine immediately || long Reliable: engine starter adopts metal materials and exquisite manufacturing technology, which can work stably even in harsh environments, greatly reducing motor failures and extending service life || Quick Start: Using advanced motor technology, the engine starter kit can reach high speed in a short period of time, quickly driving the engine to run and saving waiting time || Easy installation: structure of the high torque starter is easy to replace, and the compatibility of the installation interface is strong. It can be quickly installed and replaced, saving installation time and cost || 346-76010 Starter Motor 9 Tooth Compatible With Tohatsu Outboard M25C M30C M40C 346-76010-0

DUANLOUS Strong power: Starter Motor can provide powerful torque, making the engine easy to start. Even in cold weather, it can quickly respond and start the engine immediately || long Reliable: engine starter adopts metal materials and exquisite manufacturing technology, which can work stably even in harsh environments, greatly reducing motor failures and extending service life || Quick Start: Using advanced motor technology, the engine starter kit can reach high speed in a short period of time, quickly driving the engine to run and saving waiting time || Easy installation: structure of the high torque starter is easy to replace, and the compatibility of the installation interface is strong. It can be quickly installed and replaced, saving installation time and cost || 346-76010 Starter Motor 9 Tooth Compatible With Tohatsu Outboard M25C M30C M40C 346-76010-0

346-76010-0 346-76010-0A0 Starter Motor For Hitachi S108-98 S108-9

UWOREUE 346-76010-0 346-76010-0A0 Starter Motor For Hitachi S108-98 S108-9 || Weight : 2.45kg || OEM : 346-76010-0 346-76010-0A0 346-76010-0M || Processing customization : Yes || Application : ATVs Motorcycles || Model : MS-MT503 || Item No. : MT503

UWOREUE 346-76010-0 346-76010-0A0 Starter Motor For Hitachi S108-98 S108-9 || Weight : 2.45kg || OEM : 346-76010-0 346-76010-0A0 346-76010-0M || Processing customization : Yes || Application : ATVs Motorcycles || Model : MS-MT503 || Item No. : MT503

Nissan entire parts catalog list:

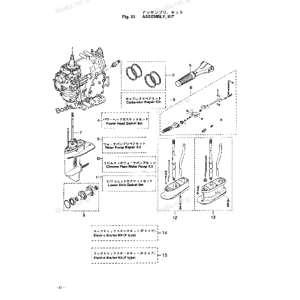

- ASSEMBLY KIT » 346-76010-0

- ELECTRIC STARTER (P & F TYPES) » 346-76010-0

- ELECTRIC STARTER (P & F TYPES) » 346-76010-0

- ASSEMBLY KIT » 346-76010-0

- ASSEMBLY KIT » 346-76010-0

- ELECTRIC STARTER » 346-76010-0

- ELECTRIC STARTER (EP TYPE) » 346-76010-0

Information:

Refer to Special Instruction, SEHS9278 for the instructions on the use of the 4C-8753 Extended Collet .Fuel setting is the adjustment of the fuel setting screw to a specified position. The fuel setting screw limits the power output of the engine by setting the maximum travel of all the fuel injector racks.

Illustration 1 g00323603

Synchronization and fuel setting tools (1) 8T-2684 Rack Synchronization Gauge (2) 6V-3075 Dial Indicator (3) 4C-8753 Extended Collet (4) 5P-7263 Indicator Contact Point Before the fuel setting is checked, the injectors must be correctly synchronized. Refer to Testing And Adjusting, "Fuel Injector Synchronization". After the injectors are synchronized correctly, leave the synchronization pin in place for the procedure that follows.

Put 6V-3075 Dial Indicator (2) with 5P-7263 Indicator Contact Point Contact Point (4) in 4C-8753 Extended Collet (3). Remove the plug from the right side of fuel setting cover (8) .

Illustration 2 g00323643

Installed dial indicator (typical example) (2) 6V-3075 Dial Indicator with 5P-7263 Indicator Contact Point (3) 4C-8753 Extended Collet

Move the governor or the actuator terminal shaft toward the ON position. The flat face of fuel stop lever (6) should make contact with synchronization pin (5). Hold the linkage in this position.

Illustration 3 g00323663

(2) 6V-3075 Dial Indicator (4) 5P-7263 Indicator Contact Point (5) Synchronization pin (6) Fuel stop lever

Install dial indicator (2) and extended collet (3) in the threaded hole. After indicator contact point (4) touches fuel stop lever (6), slide dial indicator (2) until the indicator reads zero. Keep the dial indicator in this position by tightening collet (3) .

Illustration 4 g00805403

Checking fuel setting (typical example) (2) 6V-3075 Dial Indicator (5) Synchronization pin (8) Fuel setting cover

Unscrew synchronization pin (5) by 25 mm (1 inch) or remove synchronization pin (5). Slowly move the governor or the actuator terminal shaft toward the fuel ON position until the flat face of the fuel stop lever is against the end of the fuel setting screw. The dial indicator reading will be the present fuel setting when the linkage is held in this position.Note: Refer to the TMI (Technical Marketing Information) for the correct fuel setting.

If the fuel setting is correct, remove the dial indicator and the synchronization pin. Install the two plugs, and install the synchronization pin back into cover (8) .

If the fuel setting needs adjustment, see "Fuel Setting Adjustment".

A mechanic with governor and fuel setting training is the ONLY one to make adjustments to the engine fuel setting.

Fuel Setting Adjustment

Cut the seal wire and remove fuel setting cover (8) and the gasket. Loosen locknut (7). Hold the fuel stop lever against the end of the fuel setting screw. Turn the fuel setting screw clockwise or counterclockwise until the correct reading is on the dial indicator.

Illustration 5 g00323705

Adjustment of the fuel setting screw (typical example)

Now tighten locknut (7). Be sure that the fuel setting screw does not turn when the locknut is tightened. Release the fuel system linkage and move the linkage toward the fuel ON position. Check the dial indicator reading again in order to be sure that the fuel setting is still correct.

Remove dial indicator (2) and synchronization pin (5). Install the two plugs.

Illustration 6 g00323706

Installed cover (typical example) (7) Locknut (8) Fuel setting cover

Put fuel setting cover (8) and the gasket in position over the fuel setting screw. Install the bolt and synchronization pin (5) in the cover. Install a new seal wire.

Illustration 1 g00323603

Synchronization and fuel setting tools (1) 8T-2684 Rack Synchronization Gauge (2) 6V-3075 Dial Indicator (3) 4C-8753 Extended Collet (4) 5P-7263 Indicator Contact Point Before the fuel setting is checked, the injectors must be correctly synchronized. Refer to Testing And Adjusting, "Fuel Injector Synchronization". After the injectors are synchronized correctly, leave the synchronization pin in place for the procedure that follows.

Put 6V-3075 Dial Indicator (2) with 5P-7263 Indicator Contact Point Contact Point (4) in 4C-8753 Extended Collet (3). Remove the plug from the right side of fuel setting cover (8) .

Illustration 2 g00323643

Installed dial indicator (typical example) (2) 6V-3075 Dial Indicator with 5P-7263 Indicator Contact Point (3) 4C-8753 Extended Collet

Move the governor or the actuator terminal shaft toward the ON position. The flat face of fuel stop lever (6) should make contact with synchronization pin (5). Hold the linkage in this position.

Illustration 3 g00323663

(2) 6V-3075 Dial Indicator (4) 5P-7263 Indicator Contact Point (5) Synchronization pin (6) Fuel stop lever

Install dial indicator (2) and extended collet (3) in the threaded hole. After indicator contact point (4) touches fuel stop lever (6), slide dial indicator (2) until the indicator reads zero. Keep the dial indicator in this position by tightening collet (3) .

Illustration 4 g00805403

Checking fuel setting (typical example) (2) 6V-3075 Dial Indicator (5) Synchronization pin (8) Fuel setting cover

Unscrew synchronization pin (5) by 25 mm (1 inch) or remove synchronization pin (5). Slowly move the governor or the actuator terminal shaft toward the fuel ON position until the flat face of the fuel stop lever is against the end of the fuel setting screw. The dial indicator reading will be the present fuel setting when the linkage is held in this position.Note: Refer to the TMI (Technical Marketing Information) for the correct fuel setting.

If the fuel setting is correct, remove the dial indicator and the synchronization pin. Install the two plugs, and install the synchronization pin back into cover (8) .

If the fuel setting needs adjustment, see "Fuel Setting Adjustment".

A mechanic with governor and fuel setting training is the ONLY one to make adjustments to the engine fuel setting.

Fuel Setting Adjustment

Cut the seal wire and remove fuel setting cover (8) and the gasket. Loosen locknut (7). Hold the fuel stop lever against the end of the fuel setting screw. Turn the fuel setting screw clockwise or counterclockwise until the correct reading is on the dial indicator.

Illustration 5 g00323705

Adjustment of the fuel setting screw (typical example)

Now tighten locknut (7). Be sure that the fuel setting screw does not turn when the locknut is tightened. Release the fuel system linkage and move the linkage toward the fuel ON position. Check the dial indicator reading again in order to be sure that the fuel setting is still correct.

Remove dial indicator (2) and synchronization pin (5). Install the two plugs.

Illustration 6 g00323706

Installed cover (typical example) (7) Locknut (8) Fuel setting cover

Put fuel setting cover (8) and the gasket in position over the fuel setting screw. Install the bolt and synchronization pin (5) in the cover. Install a new seal wire.

Parts starter Nissan:

346-76040-0

346-76040-0 STARTER SOLENOID

NS120A2, NS140A2, NS15D2, NS18E2, NS25C3, NS30A4, NS40C, NS40D2, NS40D2, NS40D2, NS50D2, NS60C, NS70C, NS8B, NS9.8B, NS9.9D2

3B2-76147-1

3B2-76147-1 STARTER CORD 1 1

NS15D2, NS18E2, NS25C3, NS30A4, NS40C, NS8B, NS9.8B, NS9.9D2, NSF8A, NSF8A2, NSF8A3, NSF9.8A, NSF9.8A2, NSF9.8A3

345-05004-0

338-05019-0

345-05105-1

345-05132-0

345-05013-1

345-05901-1